Mechanical CAD Courses

Mechanical CAD Courses in Nashik – Master CAD for Mechanical Engineering

Unlock your mechanical design potential with industry-aligned Mechanical CAD Courses at CADD Centre Nashik. Our programs are designed to transform beginners and engineering professionals into skilled CAD designers, ready for high-demand roles in product design, manufacturing, and engineering industries. With practical hands-on training, real-world projects, and expert instructors, you’ll build job-ready skills in the most widely used mechanical CAD tools.

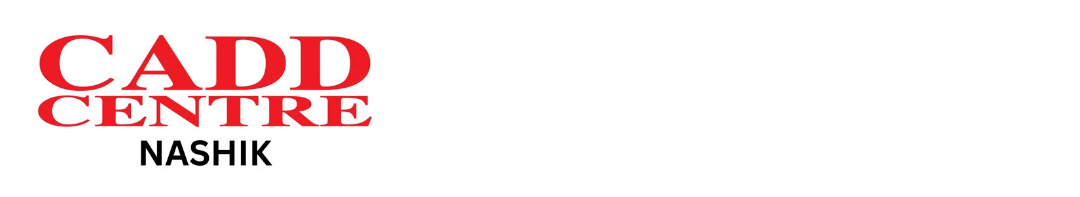

AutoCAD Mechanical

Overview:

This course focuses on AutoCAD Mechanical, a specialized version of AutoCAD designed for mechanical engineers. Participants will learn to create detailed 2D and 3D mechanical drawings, emphasizing precision and efficiency. Topics include mechanical design tools, part modeling, assembly design, and documentation.

Duration: Typically ranges from 40 to 60 hours.

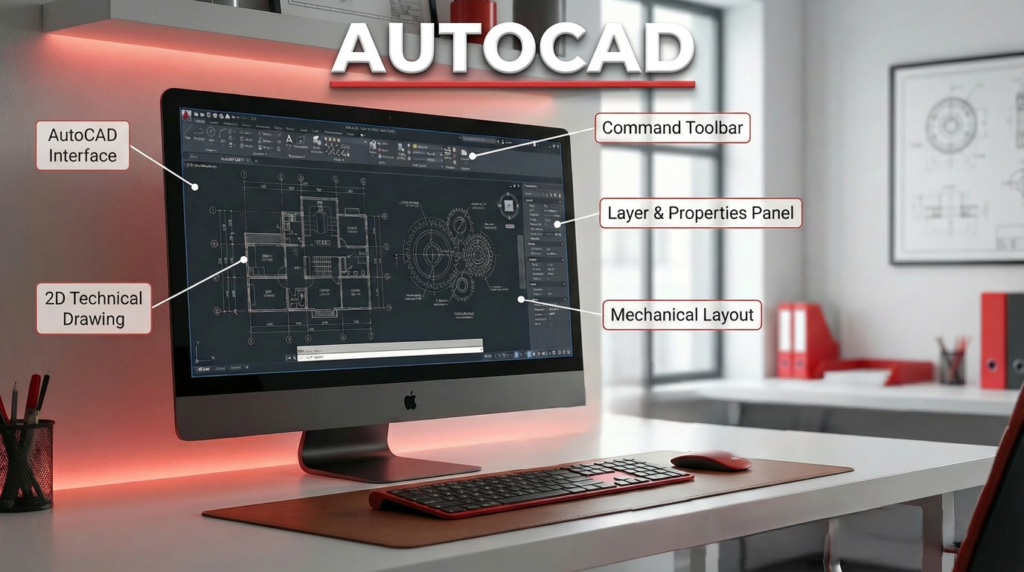

Solid Works for Mechanical Design

Overview:

SolidWorks for Mechanical Design is a comprehensive program covering 3D modeling, assemblies, and simulations. Participants will gain hands-on experience in creating parametric models, designing assemblies, and performing simulations for product development. The course is tailored for mechanical engineers and product designers.

Duration: Usually spans 60 to 80 hours.

NX CAD for Product Design and Manufacturing

Overview:

NX CAD for Product Design and Manufacturing provides in-depth knowledge of Siemens NX software. Participants will explore parametric modeling, assembly design, and Computer-Aided Manufacturing (CAM). The course is designed to equip engineers with the skills required for end-to-end product development.

Duration: Usually extends over 80 to 120 hours.

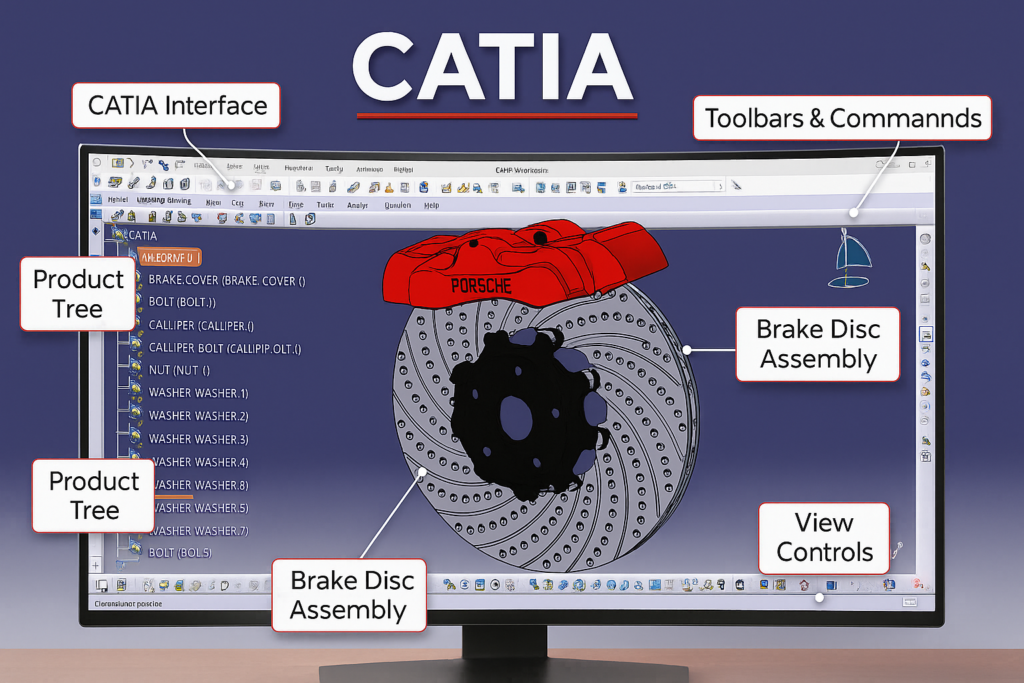

CATIA V5 for Mechanical Engineering

Overview:

This specialized course focuses on CATIA V5, a powerful CAD tool widely used in the mechanical engineering industry. Participants will learn advanced techniques for designing complex 3D models, creating assemblies, and conducting stress analysis. The course is ideal for those seeking proficiency in high-end mechanical design.

Duration: Typically takes around 80 to 100 hours.

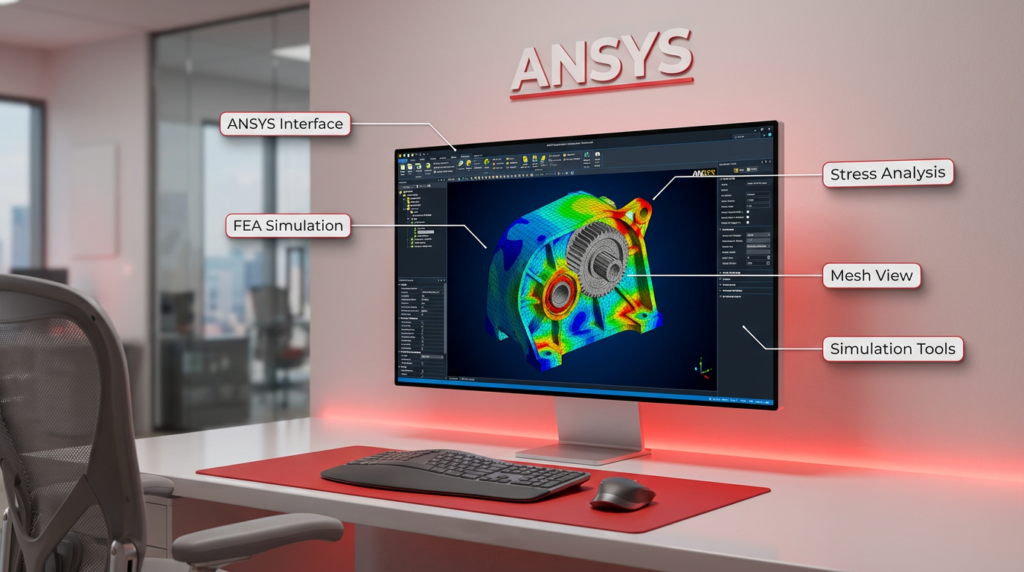

Ansys

Overview:

Discover the power of Ansys, a comprehensive simulation software suite tailored for engineers and designers. This course delves into various aspects of Ansys, equipping participants with the skills to simulate and analyze mechanical, structural, fluid, and thermal behaviors of their designs. From finite element analysis (FEA) to computational fluid dynamics (CFD), learn to leverage Ansys for accurate predictions and optimization of engineering systems.

Duration: Typically spans 40 to 60 hours, offering a deep dive into Ansys functionalities and practical application across diverse engineering domains.

Creo Parametric for Mechanical Engineers

Overview:

This course focuses on Creo Parametric, offering a comprehensive understanding of parametric 3D modeling. Participants will learn to simulate product behavior, create detailed engineering drawings, and enhance their skills in mechanical design. The course is suitable for engineers aiming for proficiency in Creo Parametric.

Duration: Typically covers 60 to 80 hours.

Mechanical Design Course Modules

This mechanical design program is structured to build strong fundamentals, followed by design thinking and industry-oriented practices, ensuring students become job-ready mechanical designers.

Module 01

Basics of Engineering Drawing

This module builds the foundation of mechanical engineering graphics, which is essential for understanding and creating technical drawings used in industries.

What You Will Learn:

Fundamentals of engineering drawing principles

Types of lines used in technical drawings

Geometric constructions

Projection methods and drawing standards

Engineering drawing conventions for accuracy and clarity

Key Topics:

Engineering Drawing Basics

✔ Types of Views (Orthographic, Isometric, etc.)

✔ Angles of Projection (First Angle & Third Angle)

Module 02

Material Selection

This module focuses on selecting the right material for the right application, which is a critical skill in mechanical design and manufacturing.

What You Will Learn:

Understanding different engineering materials

Material properties and behavior

Applications and limitations of materials

Guidelines for selecting materials in product design

Key Topics:

✔ Material Classification (Metals, Polymers, Composites, etc.)

✔ Mechanical & Physical Properties of Materials

✔ Material Selection Guidelines for Design

Module 03

Design Concepts

This module introduces the core principles of mechanical design, combining creativity with engineering logic.

What You Will Learn:

Fundamentals of design thinking

Problem-solving techniques in engineering design

Importance of aesthetics, functionality, and manufacturability

Designing products with a user-centric approach

Key Topics:

✔ User-Centric Design

✔ Parameters of Product Design

✔ Design for Functionality & Manufacturability

Module 04

Geometric Dimensioning and Tolerancing (GD&T)

This module focuses on precision and accuracy in mechanical drawings, a critical industry requirement.

What You Will Learn:

Principles and applications of GD&T

Dimensional tolerances and limits

Interpretation of GD&T symbols in drawings

Applying GD&T to parts and assemblies

Key Topics:

✔ GD&T Basics

✔ Dimensional Tolerances

✔ GD&T Symbols & Specifications